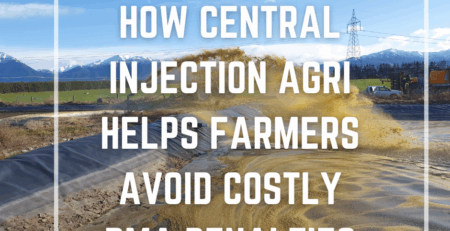

Slurry Application Techniques from Central Injection Agri

Dispersing slurry onto paddocks is a critical agricultural practice in Canterbury and New Zealand, where dairy farming is a significant component of the economy.

Proper slurry application is essential for soil health, pasture growth, and environmental sustainability. A variety of methods are used for slurry dispersion, and Central Injection Agri will outline each one along with its respective advantages and challenges. In this article, we will examine the different techniques and evaluate their effectiveness.

1. Surface Spreading

Surface spreading entails the direct application of slurry onto the soil surface using tankers or specialised machinery. This method is simple and enables rapid coverage of extensive areas. Many farmers in Canterbury favour surface spreading due to its cost-effectiveness. Central Injection Agri started with slurry tankers, which continue to be highly efficient, especially for solid manure. Our large slurry tanks transport the slurry to fields, where we distribute it effectively on the soil. This fertilizer consists of a nutrient-dense mixture of cow manure and urine effluent, fermented to enhance its effectiveness for plant growth.

However, surface spreading has several disadvantages. Nutrient loss can occur through runoff and volatilization, especially with highly soluble nutrients like nitrogen. Additionally, this method can lead to uneven distribution, which may foster localized over-fertilization and associated environmental risks, such as water pollution due to nutrient leaching.

2. Incorporation into Soil

Incorporating slurry into the soil soon after application is a method employed to minimize nutrient loss. This can be done through plowing or using specialized equipment that mixes the slurry with the soil. The incorporation can significantly reduce nitrogen loss into the atmosphere since it facilitates immediate absorption by plants.

Incorporating slurry is often more effective in terms of nutrient utilization, leading to better pasture growth. However, it requires more labor and machinery, increasing operational costs. Furthermore, there are simplistic advantages to incorporation; for instance, it may disturb soil structure and microbial ecosystems. In New Zealand, the decision to incorporate often hinges on soil type, moisture, and the timing of application relative to planting seasons.

3. Dribble Bar Application

Dribble bars consist of a series of hoses that deliver slurry close to the soil surface without significant spillage. This technique has become increasingly popular due to its ability to minimize runoff and nutrient loss while promoting even distribution. The close proximity of slurry application to plants also encourages quick nutrient uptake.

Dribble bar application can be used on various soil types and conditions and is particularly effective during wet periods when traditional spreading methods may lead to compaction and runoff issues. However, this method requires appropriate machinery, which can be costly, and may not be available for all farms.

4. Trailing Shoe Technology

Trailing shoe technology is another innovative method for slurry application. This technique uses a device that places slurry into narrow slots made in the soil, reducing soil disturbance and allowing for better nutrient retention. The trailing shoe method is efficient in capturing nitrogen and reducing odor, making it an environmentally friendly choice.

Trailing shoe application can allow farmers to spread slurry during wetter conditions without the risk of runoff, protecting waterways from nutrient entry. It does, however, require specialized equipment, capital investment, and trained operators, which might not be feasible for smaller farms.

5. Subsurface Injection: Slurry Injection

Subsurface injection entails the direct application of slurry into the soil using specialized machinery. This method is highly effective for nutrient retention, significantly reducing nutrient loss due to volatilization and ensuring optimal uptake by crops.

In New Zealand, subsurface injection is especially beneficial in areas prone to soil erosion or nutrient leaching. While this technique offers many advantages, it can be costly and labor-intensive, particularly when investing in the necessary equipment. A practical solution is to utilise the specialised machinery available from Central Injection Agri.

Central Injection Agri Ltd employs the Rotomax, which features the Veen Huis Quantra Pump unit with a capacity of up to 11,000 liters of effluent, alongside the Premium-Ject 1200 injector and a Rotomax hose reel that extends about 2.6 kilometers.

The Premium-Ject has a 12 mm width and is fitted with 60 individual discs. Each disc creates a small slot in the soil, while the 60 tubes deliver effluent directly into these slots, promoting efficient absorption into the ground.

Conclusion

The effectiveness of slurry dispersion methods in New Zealand varies widely depending on farm size, environmental conditions, and financial considerations. Surface spreading, while cost-effective, carries risks of nutrient loss, particularly in sensitive ecosystems. Incorporation can enhance efficacy but involves more labor and equipment. Dribble bars and trailing shoes represent more advanced techniques, striking a balance between minimizing environmental impacts and maintaining pasture productivity.

Subsurface injection / Slurry Injection from Central Injection Agri emerges as a leading technique in terms of nutrient retention and overall pasture health.

The choice of slurry application method should therefore include considerations around economic viability, environmental sustainability, and agronomic effectiveness, leading to better long-term outcomes for pastoral farming systems. Central Injection Agri is at the forefront of adopting innovative technologies to deliver optimal results for its clients. As advancements in slurry management continue to evolve, farmers are expected to embrace and select methods that align with their operational requirements and environmental standard.